LVT, which stands for Luxury Vinyl Tile is a durable, low maintenance and versatile flooring material, which offers the same beautiful appearance of natural wood and stone, without the practical drawbacks. At j2, our LVT is designed by our in house design team, with the sole intention to bring you, the most beautiful and authentic looking floors, which are ultimately the most practical, durable and low maintenance.

What is LVT Flooring?

What are the benefits of LVT Flooring?

Compared to natural flooring materials such as wood, ceramic and porcelain, LVT flooring is practically superior in every sense. A versatile floor, suitable for all areas of the home, LVT excels in problem areas such as bathroom and kitchens where moisture can be a problem.

Also, j2 Flooring LVT is manufactured to the highest standards and designed to replicate the beauty of natural materials, so much so, our floors are often mistaken for their natural counterpart. Our focus on tones and textures ensures we are always creating and evolving into the most authentic LVT flooring available.

See below for some of the many benefits LVT flooring offers

Easy to Clean & Maintain

Unlike many natural floors, all of our floors are easy to clean and follow a simple care routine

Waterproof

All j2 LVT and SPC floors are waterproof, making them ideal for problem areas such as kitchens and bathrooms

Pet Friendly

The durable construction of the wear layer, makes it ideal for pets and in particular dogs. Being easy to clean is also very handy with our four legged friends.

Suitable with Underfloor Heating Systems

All our LVT floors are compatible with all types of underfloor heating systems

Environmentally Friendly

All j2 LVT is manufactured to the highest standards and is free from formaldehyde and phthalates, as well as achieving Greenguard Gold certification for low emissions.

Guaranteed

All our floors come with a wear warranty between 12 years and lifetime, which is your peace of mind that they will stand the test of time.

How is LVT Flooring Made?

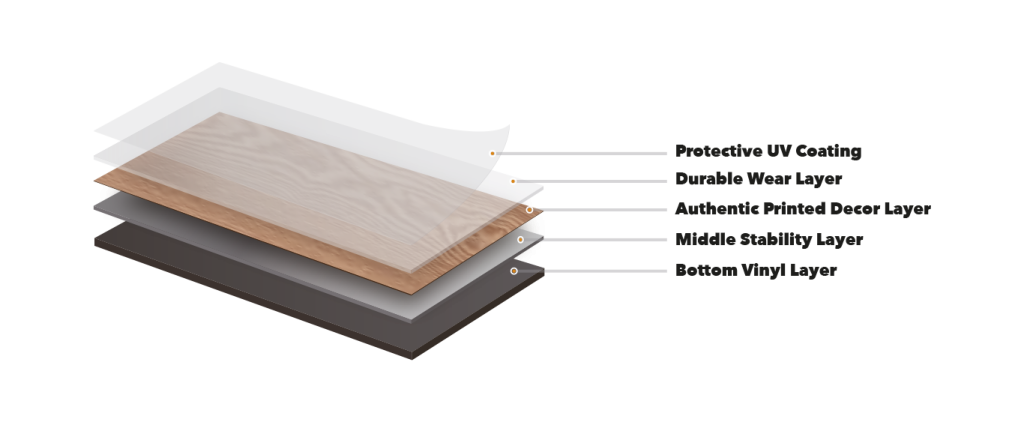

Unlike traditional forms of vinyl, which you may think of when you hear the word ‘vinyl flooring’, at j2 Flooring our LVT is made from various customised forms of vinyl and stabilising layers, to ensure an ultra durable, hardwearing and quality flooring product, which is perfect for all rooms in the home and commercial settings. To understand more about the make up of j2 LVT floors, we have created a diagram and explanation below.

1. UV Coating

This layer is a protective polyurethane coating, it is factory applied and with regular maintenance is replenished to help protect the wear layer and keep the appearance of the flooring looking better for longer.

2. Wear Layer

This is the layer that provides the durability and guarantee length. Wear layers vary on each LVT product, but the thicker the wear layer the more durable the product. Our LVT flooring is available in two different wear layer thicknesses:

0.30mm – Rustic Textures & Rustic Textures Parquet

Classed as a residential quality our 0.30mm wear layer floors are suitable for heavy domestic and light commercial.

0.55mm – Natural Timbers, Natural Timbers Parquet, Natural Stones & CREO

A 0.55mm wear layer is classified as general commercial quality, which means it is extra heavy domestic. Our 0.55mm wear layer LVT comes with a lifetime guarantee in residential locations.

3. Decor Layer

this is the film print, which gives the product its design feature. At j2 Flooring, we choose the most natural looking designs to ensure your floor is as authentic as possible.

4. Middle Stability Layer

This is an important layer to maintain the stability, balance and rigidity of the floor, especially during varying temperatures

5. Bottom Vinyl Layer

This layer works with the middle stability layer to maintain the products structure and stability. It also provides a suitable surface for the adhesive to adhere too.

Our LVT Collections

Check out the collections of glue down LVT we produce, or if you want to see everything we do in LVT click here